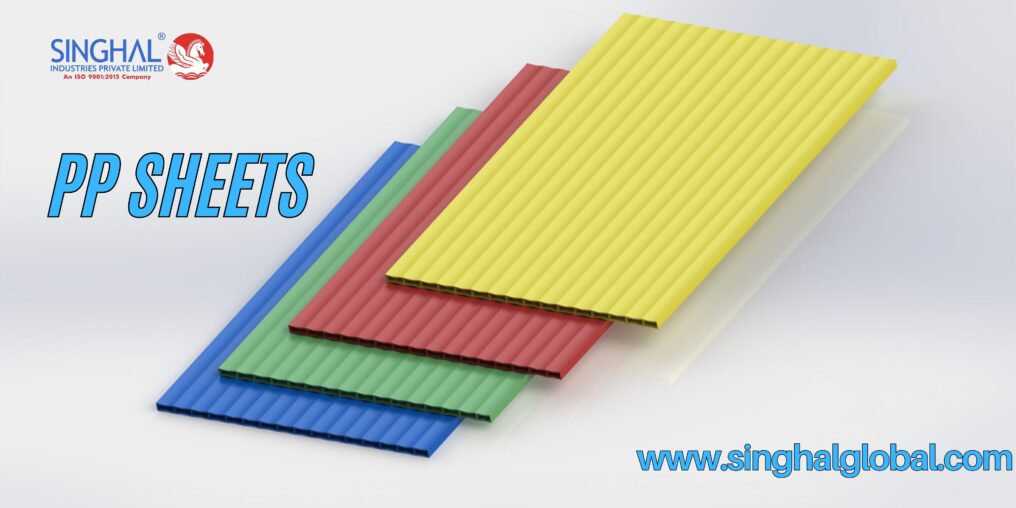

The Rise of PP Sheets in Industrial Applications

Polypropylene sheets, commonly known as PP sheets, have emerged as indispensable materials across diverse industries. From packaging and signage to automotive components and construction, these sheets combine rigidity with flexibility, offering excellent chemical resistance, impact strength, and thermal stability. In India, demand has surged, prompting many businesses to source from reliable PP sheets suppliers in India and engage with established PP sheet exporters in Gujarat.

Manufacturing Excellence in Gujarat

Gujarat has become a hub for P P sheets manufacturers in Gujarat thanks to its robust infrastructure and skilled workforce. Local plants use advanced extrusion technology to produce sheets in various thicknesses, colors, and textures. Whether you need lightweight, high-clarity sheets for display cases or heavy-duty, food-grade panels for packaging, Gujarat-based manufacturers deliver consistent quality that meets both domestic and export standards.

Key Properties That Set PP Sheets Apart

PP sheets stand out due to:

-

Chemical Resistance: Unaffected by acids, alkalis, and solvents.

-

Impact Strength: Resists cracking under stress and load.

-

Moisture Resistance: Ideal for humid environments and liquid containment.

-

Thermal Stability: Performs well in temperatures ranging from -20°C to 80°C.

Applications Across Industries

The versatility of PP sheets enables their use in:

-

Packaging: Durable crates, containers, and hygienic food packaging.

-

Construction: Wall cladding, ceiling panels, and protective barriers.

-

Automotive: Interior trim, battery casings, and under-the-hood components.

-

Retail & Signage: Displays, point-of-sale stands, and illuminated panels.

By partnering with reputable PP sheets suppliers in India, companies ensure they get the right grade for each application.

Exporting Indian-Made PP Sheets

India’s competitive manufacturing costs and stringent quality controls have positioned it as a global PP sheet supplier. PP sheet exporters in Gujarat serve markets across Africa, the Middle East, and Southeast Asia. With capabilities to handle bulk orders, provide custom cuts, and manage international logistics, these exporters help overseas buyers benefit from India’s production excellence.

Choosing the Right Supplier

Selecting a reliable supplier involves assessing:

-

Product Range: Variety of thicknesses, finishes, and grades.

-

Quality Certifications: ISO, food-grade, and RoHS compliance.

-

Customization Options: Cutting, machining, and printing services.

-

Delivery & Support: On-time shipments and technical guidance.

Engaging an experienced PP sheet exporters in Gujarat ensures smooth sourcing and product performance.

Sustainability and Recyclability

As environmental concerns grow, PP sheets offer a sustainable edge. Polypropylene is fully recyclable and can be reprocessed into new sheets or other plastic products. Many manufacturers in India incorporate recycled content, reducing waste and energy consumption. By choosing recyclable PP sheets, businesses contribute to a circular economy and reduce their environmental footprint.

Conclusion

PP sheets have transformed modern manufacturing with their durability, versatility, and cost-effectiveness. Whether sourced locally from PP sheets suppliers in India or imported from PP sheet exporters in Gujarat, these sheets meet a wide array of industrial needs. Their chemical resistance, impact strength, and recyclability make them a smart choice for businesses committed to quality and sustainability.

Frequently Asked Questions (FAQs)

Q1: What thicknesses are available for PP sheets?

PP sheets typically range from 0.5 mm to 20 mm, but custom thicknesses can be produced by major P P sheets manufacturers in Gujarat.

Q2: Are PP sheets food‑safe?

Yes. Food‑grade PP sheets meet FDA and BIS standards, making them suitable for packaging and food-contact applications.

Q3: Can PP sheets be thermoformed?

Absolutely. PP’s excellent thermoformability allows manufacturers to create complex shapes, such as trays, containers, and signage.

Q4: How do I recycle PP sheets after use?

Used PP sheets can be collected, cleaned, and sent to plastic recyclers where they are melted and re-extruded into new products, supporting sustainable manufacturing.