In the world of advanced materials, size doesn’t just matter—it defines innovation. Nanotechnology has opened doors to a new era of performance materials, and among its most powerful creations are nanocomposites. These materials, built on the nanometer scale, combine two or more distinct components to deliver exceptional strength, durability, conductivity, and more.

But what makes nanocomposites so versatile? The answer lies in their structure. By embedding nanoparticles into a matrix material, scientists have developed materials that defy traditional limitations. Whether it’s improving fuel efficiency in vehicles or enhancing drug delivery systems in healthcare, nanocomposites are making a significant impact—one tiny particle at a time.

In this guide, we’ll explore the types of nanocomposites that are shaping modern industries, discuss how they work, and highlight their growing role in the future of materials science.

What Are Nanocomposites?

Nanocomposites are multiphase solid materials where one of the phases has one, two, or three dimensions of less than 100 nanometers. In simpler terms, they are materials enhanced with nanoparticles, which significantly alter and improve their properties.

These nanoparticles can include carbon nanotubes, nanoclays, metal oxides, or other nano-sized reinforcements. The result? Lightweight materials with strength comparable to metals, or plastics with electrical conductivity. The possibilities are vast, and their use is growing rapidly across various sectors.

Why Nanocomposites Matter

Before diving into the types of nanocomposites, it’s important to understand why they matter. Nanocomposites offer:

-

Enhanced mechanical strength

-

Improved thermal stability

-

Increased electrical or magnetic properties

-

Resistance to corrosion or wear

-

Lightweight alternatives to traditional materials

From automotive and aerospace to electronics and biomedical applications, nanocomposites are helping engineers build better, safer, and more efficient products.

Main Types of Nanocomposites

Nanocomposites are generally classified based on the matrix material that holds the nanoparticles. Here are the three primary types:

1. Polymer Matrix Nanocomposites (PMNCs)

Overview

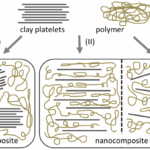

Polymer matrix nanocomposites are the most common and widely used. In these materials, nanoparticles are embedded into a polymer matrix such as polyethylene, epoxy, or nylon. The goal is to improve the mechanical, thermal, or barrier properties of the polymer.

Applications

-

Packaging: Enhanced barrier against gases and moisture

-

Automotive parts: Lightweight yet strong materials for fuel efficiency

-

Electronics: Flexible yet durable components

Nanoparticles Used

-

Nanoclays

-

Carbon nanotubes

-

Graphene

-

Metal oxides

The structure and dispersion of the nanoparticles greatly affect performance, making design and engineering crucial.

2. Metal Matrix Nanocomposites (MMNCs)

Overview

These nanocomposites involve metal matrices like aluminum, magnesium, or titanium infused with nano-scale particles. Metal matrix nanocomposites are known for their strength, wear resistance, and thermal stability, making them ideal for high-performance environments.

Applications

-

Aerospace: Structural components that endure high temperatures

-

Defense: Lightweight armor materials

-

Automotive: Engine components with improved heat resistance

Nanoparticles Used

-

Silicon carbide (SiC)

-

Boron nitride

-

Alumina (Al₂O₃)

Due to their enhanced mechanical properties, these composites are ideal for replacing heavier metals while maintaining or even improving durability.

3. Ceramic Matrix Nanocomposites (CMNCs)

Overview

Ceramic matrices are naturally brittle, but adding nanoparticles can transform them into materials with greater toughness and resistance to thermal shock. These are often used in extreme environments where high temperatures and mechanical stress are constant.

Applications

-

Aerospace engines: Components exposed to extreme heat

-

Energy: Nuclear reactors or turbines

-

Biomedical: Dental and bone implants

Nanoparticles Used

-

Zirconia

-

Silicon carbide

-

Carbon nanotubes

Although challenging to manufacture, ceramic matrix nanocomposites are opening new frontiers in energy and medical fields.

Hybrid Nanocomposites: The Next Evolution

While the above categories form the foundation, researchers are now pushing boundaries with hybrid nanocomposites—materials that combine two or more types of nanoparticles or matrix systems. This allows for customized properties and multi-functional performance, offering even greater potential in specialized fields such as flexible electronics, smart textiles, and biotechnology.

Challenges and Future Outlook

Despite their promise, nanocomposites come with their own set of challenges:

-

Uniform dispersion of nanoparticles can be difficult to achieve.

-

Scalability for commercial production is still a work in progress for many types.

-

Cost can be high due to specialized materials and processes.

-

Health and safety concerns must be carefully managed, especially when handling nano-sized particles.

However, ongoing research is addressing these issues. As synthesis techniques improve and demand increases, nanocomposites are expected to become more accessible and affordable across industries.

Real-World Impact: Datum Advanced Composites

One company paving the way in this innovative field is Datum Advanced Composites. With a commitment to precision engineering and material innovation, Datum develops high-performance nanocomposite solutions tailored for aerospace, defense, energy, and more. Their expertise ensures that industries stay ahead of the curve—leveraging the potential of nanoscale materials for maximum impact.

Conclusion

From lightweight automotive parts to high-temperature aerospace components, nanocomposites are transforming the way we think about material performance. Understanding the types of nanocomposites helps professionals and researchers make informed choices when designing for strength, durability, or efficiency.

As nanotechnology continues to evolve, these small particles will play an even bigger role in shaping the future of materials science.

Ready to Explore Nanocomposite Solutions?

Whether you’re an innovator, engineer, or industry leader, tapping into the power of nanocomposites can elevate your projects. Connect with experts like Datum Advanced Composites to explore customized solutions designed for the challenges of tomorrow.