In recent years, digital fabrication has moved from the fringes of innovation to the center of modern production. Amidst this evolution, two terms often come up—3D printing and additive manufacturing. Many people treat them as synonyms, but are they really the same?

Understanding the difference isn’t just about semantics—it’s about knowing how the technology fits into real-world applications, from hobby projects to aerospace engineering.

Let’s explore where the terms overlap, where they diverge, and why that matters for both newcomers and industry professionals.

What Is 3D Printing?

At its core, 3D printing is a process that creates physical objects from digital files. Material—usually plastic or resin—is deposited layer by layer to build up the final shape. What started as a prototyping tool has grown into a reliable method for small-scale manufacturing, design iterations, and customized production.

Because of its accessibility, 3D printing has become a household term. Desktop machines are now found in schools, startups, and even living rooms. It’s user-friendly, cost-effective, and perfect for rapid prototyping or creating detailed visual models.

What Is Additive Manufacturing?

This is the umbrella term for all layer-by-layer fabrication technologies. It includes everything from plastic-based 3D printers to industrial metal systems that build high-performance parts for critical sectors. In industrial contexts, this term reflects a higher level of precision, repeatability, and performance—often backed by strict quality control standards.

So while 3D printing is technically part of the process, this term is more commonly used when referring to high-end production, particularly in industries like aerospace, automotive, defense, and healthcare.

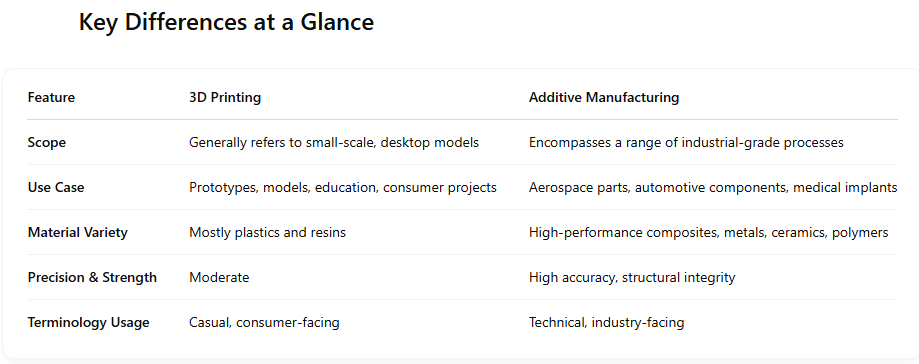

Comparing the Two: Terminology, Use, and Perception

1. Language and Context

-

3D Printing: A casual, widely recognized term, used in everyday conversations and by hobbyists or small businesses.

-

Industrial Fabrication: A term used in engineering teams, manufacturing plants, and research labs—where performance is critical and technical language matters.

The difference is similar to saying “bike” vs. “motorcycle”—both involve two wheels, but the function, speed, and purpose are very different.

2. Use Cases

-

3D Printing is commonly used for:

-

Educational models

-

Prototypes for product development

-

Artistic or decorative items

-

Custom consumer goods (e.g., phone cases, figurines)

-

-

Industrial Fabrication is ideal for:

-

Aircraft engine components

-

Lightweight automotive parts

-

Medical implants customized for patients

-

Precision tooling for manufacturing lines

-

3. Material Capabilities

The technology behind each process differs greatly in terms of materials and performance. Entry-level printers often use PLA or ABS plastics. Meanwhile, advanced systems may employ titanium, stainless steel, carbon fiber composites, or high-grade polymers designed to withstand extreme conditions.

Technologies Involved

Both concepts use similar methods at a fundamental level, but with different machines, materials, and outcomes.

Popular 3D Printing Methods

-

FDM (Fused Deposition Modeling) – Melts and extrudes filament through a nozzle.

-

SLA (Stereolithography) – Uses liquid resin cured by light for high-detail parts.

-

SLS (Selective Laser Sintering) – Uses a laser to fuse powdered materials.

Advanced Industrial Techniques

-

DMLS (Direct Metal Laser Sintering) – Fuses fine metal powder to create fully functional components.

-

EBM (Electron Beam Melting) – Uses an electron beam for high-strength parts.

-

CFR (Continuous Fiber Reinforcement) – Embeds continuous fibers to dramatically increase strength and stiffness.

Common Misconceptions

“They’re the same thing.”

Not exactly. 3D printing is one approach under the broader category of digital fabrication. It’s best understood as an entry point—a gateway into a much larger and more complex ecosystem.

“3D printing is only for prototypes.”

While that used to be true, materials and techniques have evolved. Functional end-use parts are increasingly produced using these methods, especially in custom or low-volume production.

Why the Distinction Matters

For engineers and manufacturers, using the right term reflects technical understanding. Clients, investors, and collaborators may base important decisions on your language. Saying you use “3D printing” when you’re producing flight-ready aerospace parts may downplay the sophistication of your process.

At the same time, for everyday users, the simplicity of “3D printing” makes the technology feel more approachable and exciting.

Real-World Example: Datum Advanced Composites

Companies like Datum Advanced Composites are redefining what digital fabrication means. By pushing material science and manufacturing capabilities to new heights, they’re helping industries unlock stronger, lighter, and more efficient components for real-world applications. This is where the evolution of 3D printing has matured into something far more powerful—precision, performance, and scale.

Final Thoughts

So, what’s the takeaway?

-

Use 3D printing when talking about consumer-grade, prototype, or artistic production.

-

Use industrial fabrication when referring to high-performance parts made for critical systems.

-

Understand that while the terms are connected, the expectations and applications they carry are vastly different.

In the end, they both point to a shared future—one where making things is faster, smarter, and more sustainable than ever before.

Ready to explore how advanced digital fabrication can transform your products?

Whether you’re designing, prototyping, or scaling up for production, choosing the right technology—and the right partner—can make all the difference.